Product Description

Product Description

We are the leading top Chinese coupling manufacturer, and are specializing in various high quality HRC coupling.

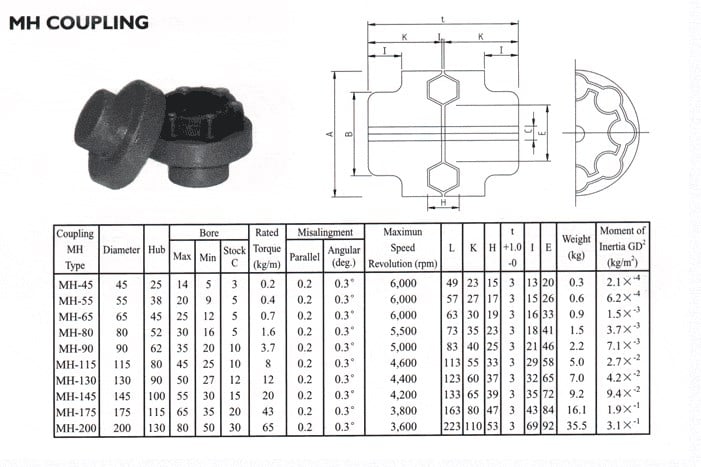

KASIN MH Shaft Couplings

1. Material:the hub of the Couplings is Cast Iron,the Elastomer is Rubbe

2. OEM and ODM are available

3. High efficient in transmission

4. Finishing:The surface treatment is normally Phosphated and painting

5. High quality with competitive price

6. Different models suitable for your different demands

7. Stock for different bore size on both sides available.

8. Application in wide range of environment.

9. Quick and easy mounting and disassembly.

10. Resistant to oil and electrical insulation.

11. Identical clockwise and anticlockwise rotational characteristics.

12. Small dimension, low weight, high transmitted torque.

13. It has good performance on compensating the misalignment.

14.Feature of couplings:free of maintenance,simple structure and easy to install.

15.Application:Mainly used in the mining, metallurgical, cement, chemicals, construction, building materials, electric power, telecommunications, textiles, and transportation departments.

Techncial Date

Related Products

Roller Chain Coupling FCL Coupling Curved Jaw Coupling

Manufacturing

Applications:

NM couplings are offered in the industry’s largest variety of stock bore/keyway combinations. These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion power transmission applications. Applications include power transmission to industrial equipment such as pumps, gear boxes, compressors, blowers, mixers, and conveyors.

About Us

Kasin group was established in 1989, and its first product is casting carrier trolley for power & free conveyor system. In 1995, CHINAMFG purchased HangZhou Guoping Forging Factory (LYGP), a marketer of forging bolts & nuts to power & free line market in china. With this acquisition, CHINAMFG positioned itself as 1 of major parts suppliers of monorail and power & free conveyor system in china.

In 2/8822 0571 -57152031 Fax: 86~/8822 0571 -57152030

Http://kasinchain

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 27-90 |

| Torque: | >80N.M |

| Bore Diameter: | as Your Require |

| Speed: | 3500 |

| Structure: | Flexible |

| Samples: |

US$ 8/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can flexible couplings handle misalignment between shafts?

Yes, flexible couplings are specifically designed to handle misalignment between shafts in rotating machinery and mechanical systems. Misalignment can occur due to various factors, including installation errors, thermal expansion, manufacturing tolerances, or shaft deflection during operation.

Flexible couplings offer the ability to compensate for different types of misalignment, including:

- Angular Misalignment: When the shafts are not collinear and have an angular offset, flexible couplings can accommodate this misalignment by flexing or twisting, allowing the two shafts to remain connected while transmitting torque smoothly.

- Parallel Misalignment: Parallel misalignment occurs when the two shafts are not perfectly aligned along their axes. Flexible couplings can adjust to this misalignment, ensuring that the shafts remain connected and capable of transmitting power efficiently.

- Axial Misalignment: Axial misalignment, also known as end float or axial displacement, refers to the relative axial movement of the two shafts. Some flexible coupling designs can accommodate axial misalignment, allowing for slight axial movements without disengaging the coupling.

The ability of flexible couplings to handle misalignment is essential in preventing premature wear and failure of the connected equipment. By compensating for misalignment, flexible couplings reduce the stress on the shafts, bearings, and seals, extending the service life of these components and improving overall system reliability.

It is crucial to select the appropriate type of flexible coupling based on the specific misalignment requirements of the application. Different coupling designs offer varying degrees of misalignment compensation, and the choice depends on factors such as the magnitude and type of misalignment, the torque requirements, and the operating environment.

In summary, flexible couplings play a vital role in handling misalignment between shafts, ensuring efficient power transmission and protecting mechanical systems from the adverse effects of misalignment. Their ability to accommodate misalignment makes them indispensable components in various industrial, automotive, aerospace, and marine applications.

Can flexible couplings be used for both motor-to-shaft and shaft-to-shaft connections?

Yes, flexible couplings can be used for both motor-to-shaft and shaft-to-shaft connections in various applications. The versatility of flexible couplings allows them to adapt to different types of connections and meet the specific requirements of the system.

Motor-to-Shaft Connections:

When connecting a motor to a shaft, a flexible coupling serves as an intermediary component that joins the motor shaft and the driven shaft. Flexible couplings are commonly used in motor-driven systems to accommodate misalignment between the motor and the driven load. In motor applications, flexible couplings help reduce stress and wear on the motor bearings, thus extending the motor’s life and enhancing overall system reliability. They also act as vibration dampeners, minimizing vibrations transmitted from the motor to the driven shaft, and subsequently to connected equipment, ensuring smoother operation.

Shaft-to-Shaft Connections:

In many mechanical systems, such as those in the manufacturing, automation, and power transmission industries, shaft-to-shaft connections are required. A flexible coupling can bridge the gap between two shafts and transmit torque while accommodating misalignment. This type of coupling is commonly used to connect shafts that are not perfectly aligned due to factors like manufacturing tolerances, thermal expansion, or foundation settling. By allowing for misalignment, the flexible coupling protects the connected components from excessive stresses and ensures efficient power transmission.

Versatility and Advantages:

The ability of flexible couplings to handle both motor-to-shaft and shaft-to-shaft connections makes them versatile solutions for a wide range of industrial applications. Some of the advantages of using flexible couplings in these connections include:

- Minimizing stress and wear on connected components, such as bearings and seals.

- Compensating for misalignment, ensuring smooth power transmission.

- Damping vibrations and shock loads, reducing the risk of mechanical failures.

- Protecting equipment from excessive forces, enhancing system reliability.

- Simplifying installation and alignment procedures, reducing downtime.

- Improving overall system performance and operational efficiency.

Applications:

Flexible couplings find applications in a wide range of industries, including manufacturing, material handling, automotive, aerospace, robotics, and more. Whether connecting a motor to a shaft or joining two shafts directly, flexible couplings play a crucial role in enhancing the reliability and efficiency of rotating machinery and mechanical systems.

In conclusion, flexible couplings can effectively serve as connectors for both motor-to-shaft and shaft-to-shaft connections, providing essential misalignment compensation and protection for connected equipment in various industrial applications.

Are there any limitations or disadvantages of using flexible couplings?

While flexible couplings offer numerous advantages, they do come with some limitations and disadvantages that should be considered when selecting them for specific applications. Here are some of the common limitations and disadvantages of using flexible couplings:

- Torsional Stiffness: Flexible couplings provide some level of torsional flexibility, which is advantageous in many applications. However, in systems that require high precision and minimal angular deflection, the inherent flexibility of the coupling may not be suitable. In such cases, a rigid coupling may be more appropriate.

- Limitation in High-Torque Applications: While some flexible couplings can handle moderate to high torque levels, they may not be as well-suited for extremely high-torque applications. In such cases, specialized couplings, such as gear couplings, may be required to handle the high torque demands.

- Temperature Limitations: The performance of certain flexible coupling materials, especially elastomers and plastics, may be affected by extreme temperature conditions. High temperatures can lead to premature wear and reduced lifespan of the coupling, while low temperatures may result in reduced flexibility and potential brittleness.

- Chemical Compatibility: Certain flexible coupling materials may not be compatible with certain chemicals or substances present in the application’s environment. Exposure to chemicals can cause degradation or corrosion of the coupling material, affecting its performance and lifespan.

- Installation and Alignment: Flexible couplings require proper installation and alignment to function effectively. If not installed correctly, misalignment issues may persist, leading to premature wear and reduced performance. Aligning the shafts accurately can be time-consuming and may require specialized equipment and expertise.

- Cost: In some cases, flexible couplings may be more expensive than rigid couplings due to their more complex design and use of specialized materials. However, the cost difference is often justified by the benefits they offer in terms of misalignment compensation and vibration damping.

- Service Life: The service life of a flexible coupling can vary depending on the application’s conditions and the quality of the coupling. Regular maintenance and timely replacement of worn or damaged parts are essential to ensure the coupling’s longevity and prevent unexpected failures.

Despite these limitations, flexible couplings remain highly valuable components in a wide range of applications, providing efficient torque transmission and compensating for misalignment. Proper selection, installation, and maintenance can help mitigate many of the disadvantages associated with flexible couplings, ensuring their reliable and long-lasting performance in various mechanical systems.

editor by CX 2024-04-12

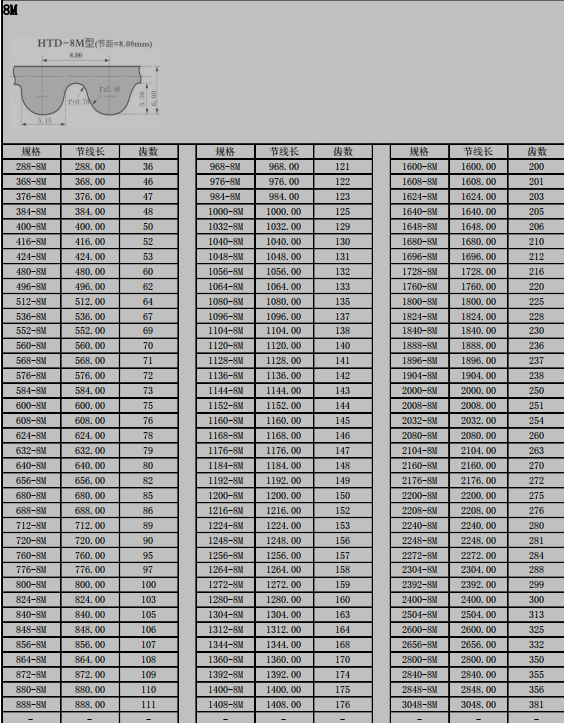

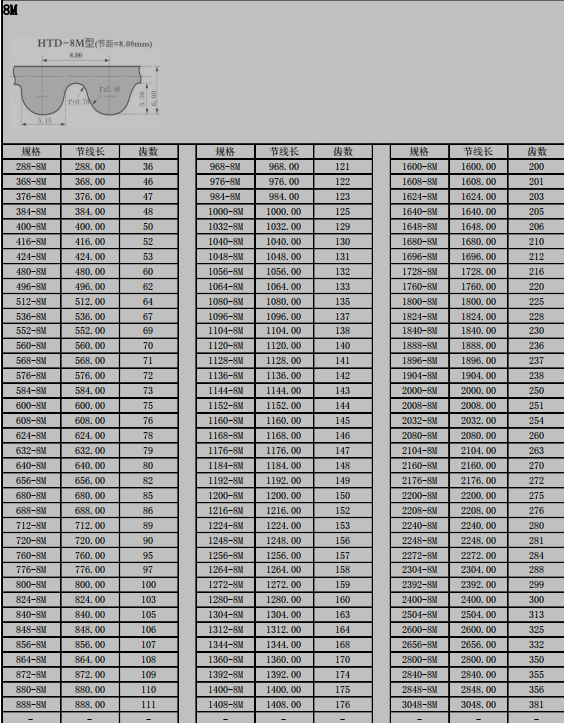

China manufacturer & factory supplier for China in Durgapur India manufacturer Packing machine 8M 776mm length 20mm belt width timing belt With high quality best price & service

We assistance a nationwide foundation of Industrial Distributors, and Authentic Equipment Makers as well as Agricultural Tools Manufacturers and Wholesalers. Found in Memphis, TN we are at the middle of 1 of the biggest distribution hubs in the country and with our extensive inventory stages and limitless delivery alternatives, we are capable to give our customers with exact on-time deliveries.Our company pays particular consideration to customers’ requirements, listening to the distinct demands of every consumer and guaranteeing total fulfillment.

Overview

Rapid Specifics

- Applicable Industries:

-

Creating Material Stores, Production Plant, Machinery Repair Retailers, Meals & Beverage Manufacturing facility, Farms, Power & Mining

- Product identify:

-

Timing belt

- Colour:

-

Black

- Application:

-

Electricity Transmission Belt

- Size:

-

Common Dimension

- Characteristic:

-

Reduced Noisy

-

Duration:

Our factory has attained the certificate of China’s Farm Equipment Products Good quality Authentication promulgated by the Farm Machinery Merchandise High quality Authentication Centre of China. -

288-3048mm

- Packing:

-

Cartons

- Pitch:

-

8mm

- Benefit:

-

Higher functionality

- Teeth:

-

36-381

Provide Capability

- Source Ability:

- 5000 Meter/Meters for each Thirty day period

Packaging & Shipping and delivery

- Packaging Information

- Carton box+ wood scenario

- Port

- Tianjin/Shanghai/Ningbo

-

Direct Time

: -

Amount(Luggage) one – one hundred >100 Est. Time(times) 15 To be negotiated

On the internet Customization

EPG offer you widest assortment of gearbox and speed reducers, conveyor chains and transmission components like gear, sprocket, racks, pulley, shaves and taper bushes and so forth for various programs

Item Description

|

Item identify |

Timing belt |

||||||

|

Materials |

Rubber,PU, steel wire |

||||||

|

Kind |

Open up,spherical |

||||||

|

Product dimension |

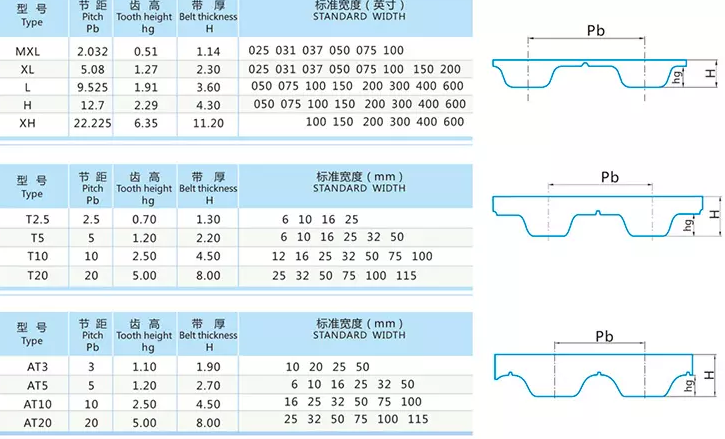

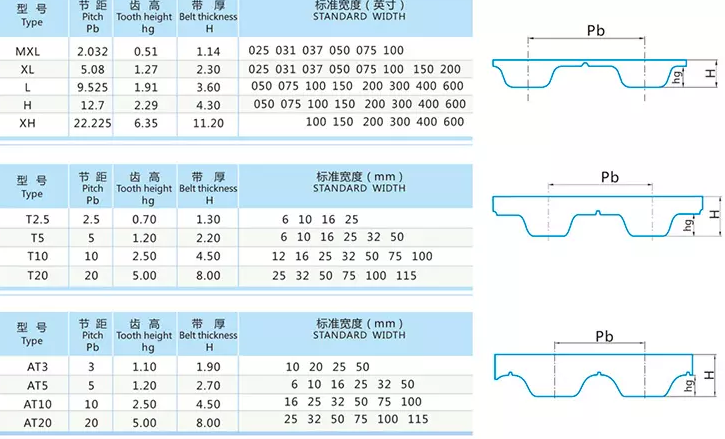

T type:MXL,XL,L,H,XH,T2.5,T5,T10,TThe PTO shaft incorporated with all Victory Tractor mowers has a for a longer time extension than the standard PTO Shaft. The additional length is essential because of the significantly achieving motion of the mowers to the appropriate of the tractor. twenty,AT5,AT10,AT20 |

||||||

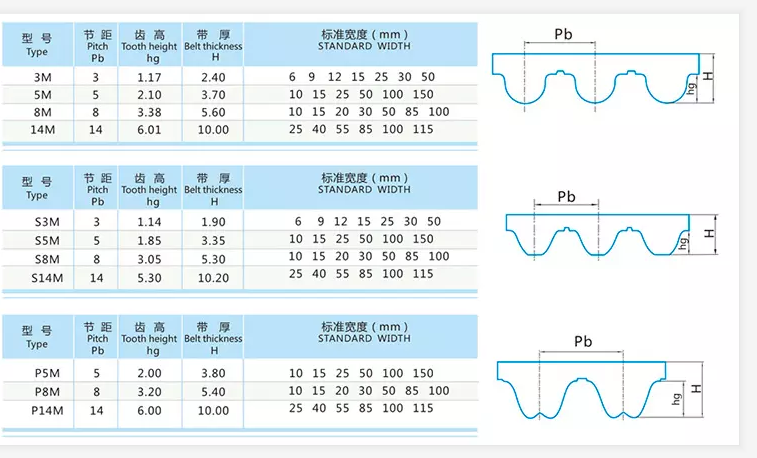

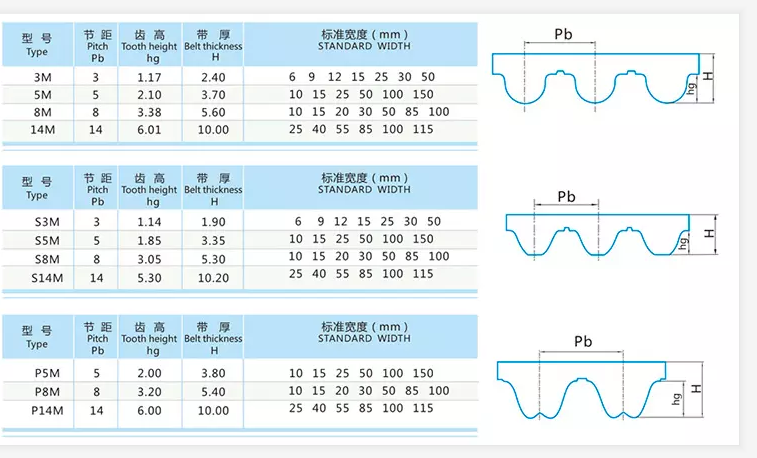

|

Arc variety:2M,3M,5M,8M,14M,20M,S2M,S3M,forty four.5M,S5M,S8MS14M |

|||||||

|

Coloration |

Black,white,environmentally friendly,ect |

||||||

|

unique place |

China |

||||||

|

Edge |

Large energy, anti oil, heat, getting older,Excellent bending resistant efficiency |

||||||

|

Feature |

1. Polyurethane Open up Finished Timing belt—-infinite extended or joined limitless variety. |

||||||

|

Software |

belt commonly employed in equipment tools, textile, printing, foods packaging, wire and cable, devices and meters, petroleum chemical, |

||||||

Diverse sort timing belt

ARC variety

T sort

Open up sort

Round sort

PU substance

Rubber content

Application

Catalog

Payment

Our Firm

HangZhou EPG – The most significant transmission elements manufacuturer in China Electrical Equipment Co.,Ltd was started in HangZhou in 2008 and is a skilled manufacturer and exporter that is concerned with the layout, growth and manufacturing.With thorough requirments, we can also develop your special made item. Our solution assortment contains all sorts of helical equipment, spur gear, bevel equipment, equipment rack, worm equipment, sprockets,chains, bearings.Retaining in thoughts that great support is the key to cooperating with consumers, we attempt to satisfy large top quality requirements, offer competitive charges and make certain prompt delivery. In this way, our merchandise have ongoing to obtain market place acceptance and clients pleasure above the earlier couple of years. We are aiming to meet up with the calls for of the consumers close to the entire world..If you are intrigued in any of our goods or would like to examine a likely get, please truly feel cost-free to get in touch with us. We are looking forward to establishing successful company relationships with new consumers about the world in the potential.

· Our Theory: “Believability Supremacy, and Buyer Initial”

· Our Promise: “High high quality products, and Excellent Service”

· Our Price: “Getting Honesty, Undertaking the Ideal, and Extended-lasting Advancement”

· Our Intention: “Develop to be a leader in the electrical power transmission parts market in the world”

EPG – The greatest transmission parts manufacuturer in China Primary Products

Industrial Sprocket

Motorcycle Sprocket

Roller Chain

Spur Equipment

Helical Equipment

Bevel Equipment

Plastic/POM/Nylon Gear

Small Pinion Gear

Worm Gear and shaft

Gear Rack

Timing Pulley

Taper Bushing

Chain Guides

Linear Rail and Block

Ball Screw